Zhejiang saitege International Co., Ltd.

Zhejiang saitege International Co., Ltd.

steel coil slitting process -The Pre painted galvanized steel coil is made by proceeding the chemistry treating (the degree,phosphorus, chromium hydrochloric acid passivation) on the surface of steel sheet( Zinc-plated,aluminum-zinc plated, nickel plated, etc.) then draw( the roller scribbles) the coating, again baking.

steel coil slitting process -The Pre painted galvanized steel coil is made by proceeding the chemistry treating (the degree,phosphorus, chromium hydrochloric acid passivation) on the surface of steel sheet( Zinc-plated,aluminum-zinc plated, nickel plated, etc.) then draw( the roller scribbles) the coating, again baking.

steel coil slitting process -It has the strength and shape-exchanging performance of the steel plate, at the same time has thegood adornment and anti-erode performance of organism material. Coating adhesive force of colorcoated sheet is strong, which keeps the color and luster novel for long time. The color coated coilis widely used in architecture, electrical home appliance, furniture, and transportation, etc.

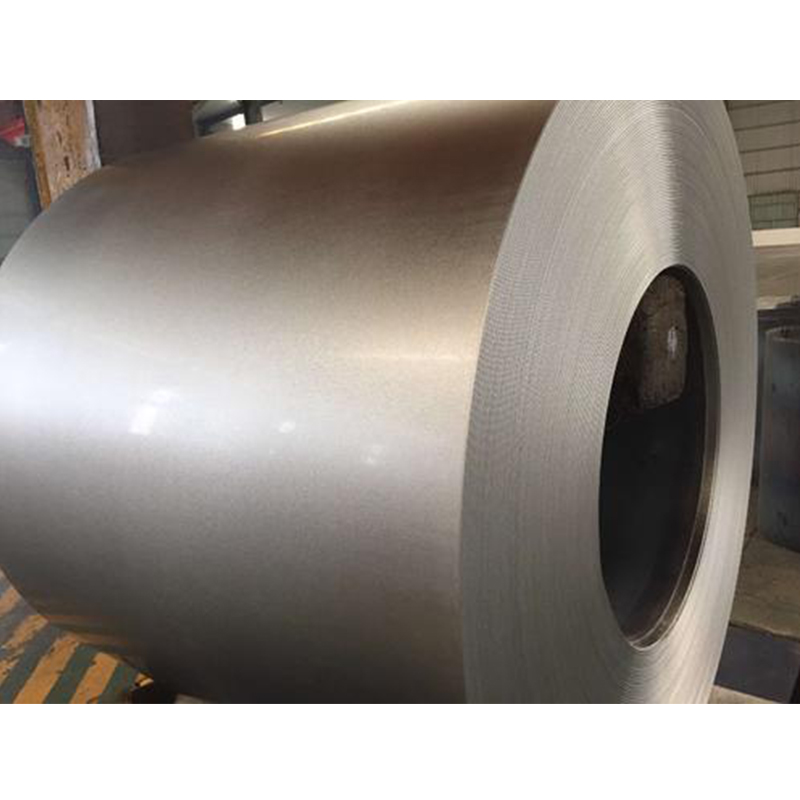

1.Hot dipped galvanized steel coil description

steel coil slitting process -Hot dipped galvanized steel coil is hot-dip galvanizing is a process that involves coating metals such as steel and iron with a thin layer of zinc.Pure zinc layer then turns into zinc oxide when it is exposed to oxygen, and finally zinc carbonate after exposure to carbon dioxide.

2.Hot dipped galvanized steel coil technical process

steel coil slitting process -After cleaning and acid pickling, the steel coil is submerged in melted zinc, a chemical reaction permanently bonds the zinc. The zinc actually permanently becomes a part of it and the successive layers are a mixture of zinc and iron.Hot dipped galvanized steel coil is a special type of steel coil used in a number of different applications within fabrication and manufacturing environments

3.Hot dipped galvanized steel coil flow chart

Decoiler--- Shearer ----welder ----pre-treatment ----entry looper--- annealing furnace--- zinc pot ---- air cooling tower ----water cooler--- leveller---- post treatment ---exit looper crimper.

4.Hot dipped galvanized steel coil main usage scope:

steel coil slitting process -Hot dipped galvanized steel coil is widely used in home appliances, kitchen utensils,handicrafts, construction formwork, granary, revealed rain,chimneys, roof tile, fire shutter doors,construction industry, as raw material for the production of corrugated panels, fencing products, drywall panel profiles, ventilation systems etc.

steel coil slitting process - Now the price of stainless steel suppliers is basically the same as long as it is a distance. If the price is too low, you need to carefully consider whether there is a quality problem.